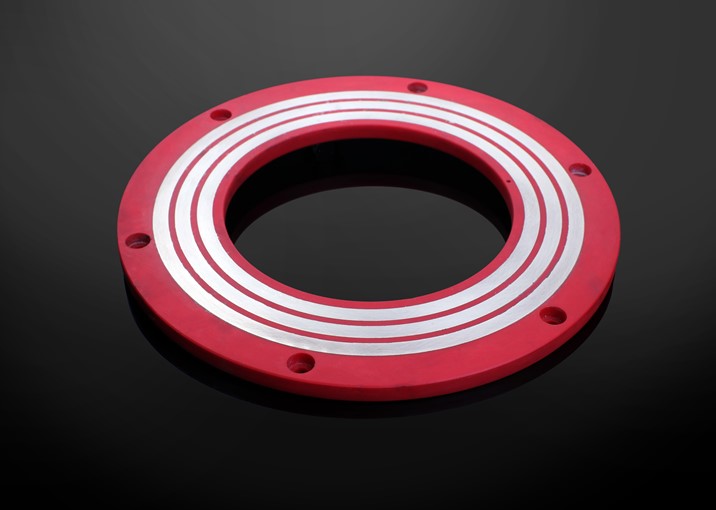

Vestas MK7 Power Slip Ring Upgrade

By working closely with wind farm owners and technicians, we continuously seek to understand the maintenance challenges associated with specific components, striving to enhance the service engineer’s experience wherever possible.

A recent improvement was identified in the encoder mount for the Vestas Mk7 Power Slip Ring. Discussions with wind turbine technicians revealed that encoders often failed before the slip rings and that removing them frequently resulted in damage to otherwise functional units. In response, we developed a simple yet innovative solution to address this issue.

“The encoder would trigger an alarm on the SCADA system and require replacement. The glue bonding the encoder to the shaft would melt under high temperatures, causing it to lose alignment.” – Wind Turbine Technician

In many cases, removing the encoder required excessive force, often leading to further damage. To resolve this, we designed an over-moulded shaft to act as a new encoder drive, which can be easily replaced and re-machined as part of a refurbishment. This prevents slip ring damage during encoder removal and increases the likelihood of successful refurbishment, ultimately saving customers money.

Design Advantages:

- Easy encoder removal without damaging the slip ring

- Over-moulded shaft for enhanced durability

- Easily replaceable and re-machined for extended lifespan

- Prevents unnecessary component damage

- Cost-effective refurbishment solution

This improvement not only extends the life of the slip ring but also reduces maintenance costs, ensuring a more efficient and cost-effective solution for wind farm operators.

Visit the BGB website for more information on Vestas MK7 Power Slip Ring Upgrade