Slip Rings in Packaging Machines: How to Source Replacements with Confidence

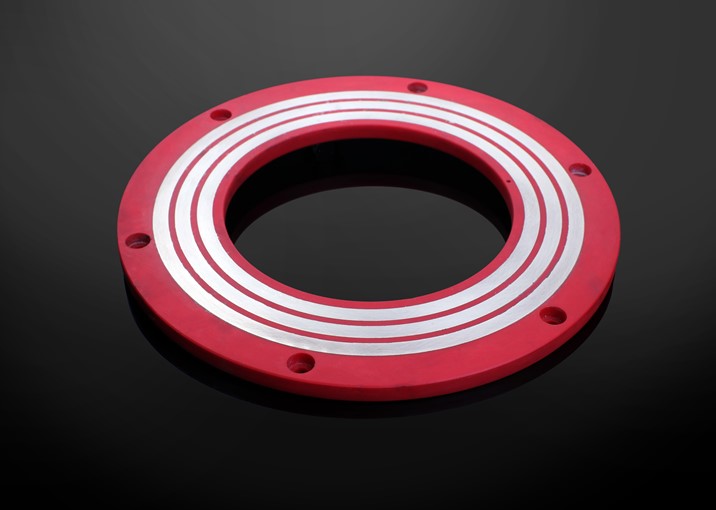

If your packaging machine relies on slip rings to transmit power and signals across rotating components, you’ll know how critical they are to keeping production running smoothly.

But what if your current slip ring supplier is no longer available? In a high-demand environment, downtime and uncertainty are the last things you need.

Practical steps to take:

-

Identify your slip ring specifications: record dimensions, circuit counts, signal types, and the operating environment so you aren’t starting from scratch.

-

Check for cross-compatibility: many slip rings can be replaced with form-fit-function alternatives that integrate into existing machines.

-

Partner with a reliable supplier: choose a manufacturer with proven packaging-sector experience, strong technical support, and a track record of long-term product availability.

-

Plan ahead: don’t wait for a failure—hold critical spares and line up a trusted backup source now.

Slip rings may be small components, but they have a big impact on uptime and efficiency. If you’re suddenly without a provider, there are solutions to keep your machines running reliably.

Contact BGB: with over 40 years’ experience supplying slip rings to the packaging sector, our specialists are ready to help. Email: sales@bgbinnovation.com.

Visit the BGB website for more information on Slip Rings in Packaging Machines: How to Source Replacements with Confidence