Continuous Improvement Helps Wind Turbine Engineers Handle Vestas Slip Rings

The Vestas V90–V126 platform has proved itself a true workhorse in the 2 MW class, with more than 20,000 turbines installed worldwide. Its 180 mm generator slip ring has earned an equally strong reputation—often delivering over a decade of service in the field.

Even the most reliable components benefit from continual improvement. Working closely with wind farm technicians, we identified common challenges and developed upgrades to extend performance and reduce costs.

Encoder mount upgrade

Premature encoder failures were frequently traced to bonded joints degrading at high temperatures. We introduced an over-moulded shaft design that simplifies encoder replacement, prevents slip ring damage during maintenance, and preserves precise central alignment.

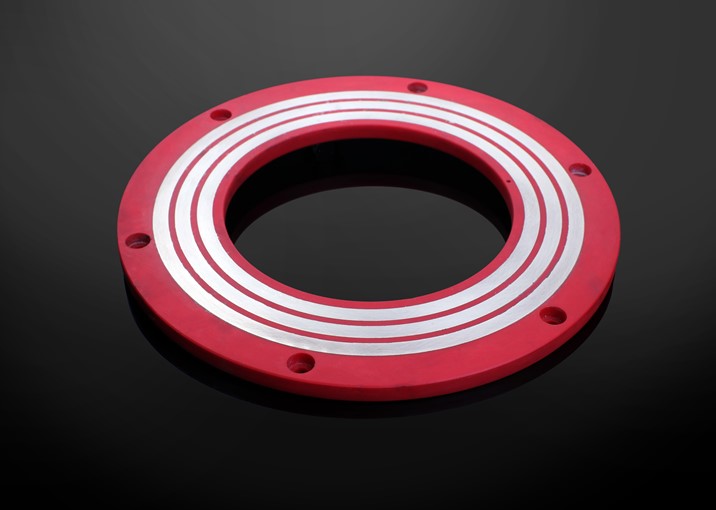

Optimised design for cost and sustainability

We reduced the terminal plate size and upgraded the hub to aerospace-grade aluminium. The result is lower material waste, improved durability, and a lighter, more efficient assembly.

Full maintenance support

Correct setup, OEM-approved silver brushes, and routine cleaning help ensure optimal operation. We also encourage recycling of silver dust and spent brushes—there’s monetary value to be recovered.

Every enhancement serves a single purpose: helping turbines run longer, safer, and more cost-effectively.

Supplied with canted coil spring connectors and fasteners, our slip ring kits ensure technicians have everything they need at height, every time.

Visit the BGB website for more information on Continuous Improvement Helps Wind Turbine Engineers Handle Vestas Slip Rings