Vibrating screen designs handle pharmaceutical and food hygiene requirements

29-05-2018

The laws, regulations, codes of practice and overall hygiene standards imposed upon the food manufacturing and pharmaceutical industry are understandably as high as they ever have been. From restaurants to food production, pharmacies to tablet manufacturing operations, every care must be taken to ensure the product remains free from contamination – and this is why processing and material handling equipment, and in particular vibrating screens, should be manufactured to the highest standards of hygiene.

A vibrating screen is used within the food manufacturing and pharmaceutical industries for a variety of applications; often as safety screens for protection against oversize particles, dedusting, fine product grading and dewatering. In the past 40 years we have helped companies screen a wide range of food products ranging from grains, cereals, dried fruits and crisps to meats and fish; and materials for the pharmaceutical industry such as tablets, powders and capsules. In the last few months alone we have removed water from cooked pasta, separated cocoa beans from broken off shell, removed leftover beverage from broken glass and sieved oversize lumps from fine powder.

In order to reduce the impact that hygiene requirements have upon budget, time and resources, vibratory screens need to be designed in such a way that are easy to install, require minimal maintenance, and are easy and efficient to use as possible. This is why the screen decks on equipment need to be easily replaced, the designs must be easy clean down and provide a long and healthy working life.

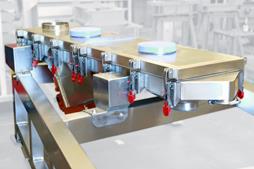

The battle for non-contamination is an easy one when it comes to using a vibrating screen, as an enclosed construction with bolted or quick release covers means that the product can be separated, dewatered or graded where dust emissions, atmospheric pollution or product contamination are to be prevented – but can be quickly opened up for inspection or clean down when required. Equipment handling hygiene sensitive materials are manufactured in stainless steel, and a range of equipment finishes (spraying, powder coating, polishing and bead blasting) can be applied to suit the requirements of the application.

Having talked to many people within the food manufacturing and pharmaceutical industries concerning the difficulties of ensuring high hygiene standards, we at Applied Vibration understand and recognise the importance of maintaining efficiency whilst adhering to the regulations. This is why our vibratory screens are always designed and suited to the particular requirements of each individual application. By designing, manufacturing and fitting our equipment in-house we can ensure that products and materials will be screened in the most effective, efficient and, most importantly, hygienic manner.