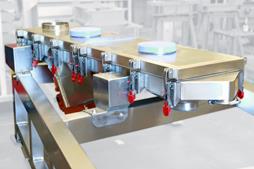

Managing and Mitigating Product Contamination Handled by Industrial Vibrating Equipment

11-07-2022

Visit the Applied Vibration Ltd website for more information on Managing and Mitigating Product Contamination Handled by Industrial Vibrating Equipment