The advantages of using a vibratory feeder, conveyor, screen or table to handle recycled materials

29-05-2018

The materials handled within the recycling industry are vast and varied; from paper and plastics to glass and wood, metals and textiles to building materials and more - and the ways in which these materials require handling through processes arguably even more so. The advantage of vibration technology is that it too is vast and varied, and the many methods of vibration handling can be used in equipment designs that solve a range of recycling applications.

Material separation by size and dewatering

In most cases, materials need to be separated out into what is usable for recycling and what is waste. A linear vibratory screen provides efficient separation by size whilst feeding onto the next process. This is often used to separate dust from usable materials, or to remove oversize pieces from bulk product – policing the material so that the usable product is separated from anything that requires further processing. In cases of bottles, particularly glass or plastic, liquid residue can often cause a problem that can be solved with a dewatering screen. By feeding the glass or plastic over a screen, vibrating equipment can separate the liquid from the material – the material feeding onto the next process or into a container, and the liquid draining out to a separate specified area. This solution is efficient and effective, and care has been taken with vibrating screen designs to ensure that clean down is easy.

Compacting materials to settle peaks and fill to capacity

When materials such as recycled plastics, glass or metal are filled into bulk bags or IBC containers, filling the containers to maximum capacity can prove tricky. The irregular parts often fill on top of one another, rather than spreading out to the corners of the container, and can also start to ‘cone’ into a peak at the top. In order to ensure filling capacity and bag stability, a vibrating table can be implemented to compact the material – encouraging movement into the corners of the container and levelling out the peaking material at the top of the bag. Low level vibratory tables sit close to the floor, and as container filling issues are usually detected prior to hopper installations, can be designed to suit pre-existing filling set ups.

Moving materials efficiently from A to B

Efficient movement of materials and transporting those materials between two locations is one of the most common requirements in the recycling industry. A vibratory conveyor, driven by twin vibrator motor drives, is well suited to such applications, providing efficient high volume conveying with low power consumption. Unlike belt conveyors, the trough or tubular structure of a vibrating conveyor does not require routine maintenance as the conveying trough does not easily wear down and there are no points in which material could get trapped. This also makes for easy clean down, reducing the amount of inefficient time within a time-conscious industry.

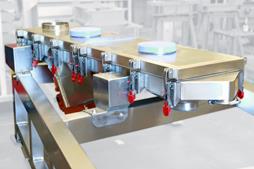

Controlling material feed for spreading over inspection belts or filling into containers

A vibratory feeder offer the same time-saving qualities such as easy clean down and low wear, but uses an electromagnetic drive that allows for control over the flow of material. This is particularly advantageous within the recycling industry when needing to regulate flow or fill a container to a certain weight. The instantaneous stop/start control allows for accuracy in precision filling applications, and the ability to slow down or speed up product flow allows for versatility in feeding a variety of materials, as often is the case with recycling processes. The control that a vibrating feeder offers is also often used to spread material over wide video inspection or picking belts – spreading the product out into a manageable stream in order to allow for effective video inspection or for an operative on the picking belt line.

With the versatility and ability to handle such a range of materials and solve a multitude of problems, industrial vibration handling equipment is one of the unsung heroes of recycled materials handling. For more information on how a vibratory conveyor, feeder, screen or table could handle a specific recycled materials application or problem, please don’t hesitate to get in touch.