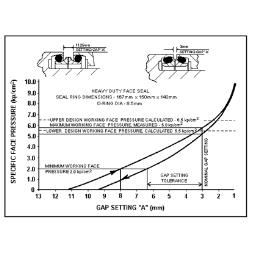

Gap Setting of the Heavy Duty Face Seals

The picture shows the load/deflection graph for a 150mm diameter seal with a 8.5mm diameter O-ring. The ideal working face pressure is about 5.5kp/cm2 - The standard Gap Setting is 3mm The elastic quality of the O-ring makes sure that small changes in the Gap Setting will result in even smaller changes in face pressure. The minimum face pressure is approximately 2.0 kp/cm2 which in this example corresponds to a Gap Setting of approximately 6.4mm. This is how the tolerance of the Gap Setting is determined. Also reducing the Gap Setting to less than 3mm is not desirable, because the face pressure will begin to rise rapidly.Visit the Sealmasters Ltd website for more information on Gap Setting of the Heavy Duty Face Seals