Inseto’s Geographical Remit Extends: Now Supplying Wafer Dicing Blades in Austria, Germany, Ireland, the Netherlands, Portugal and the UK

Inseto, a leading technical distributor of equipment and materials, has been appointed as Kulicke & Soffa’s exclusive distributor for high-quality hubbed dicing blades in Austria, Germany, the Netherlands, and Portugal. This appointment extends Inseto’s geographical remit, as the company has been supplying K&S dicing blades – along with wire and wedge bonders, dispensing equipment, and die bonders – in the UK and Ireland since 2008.

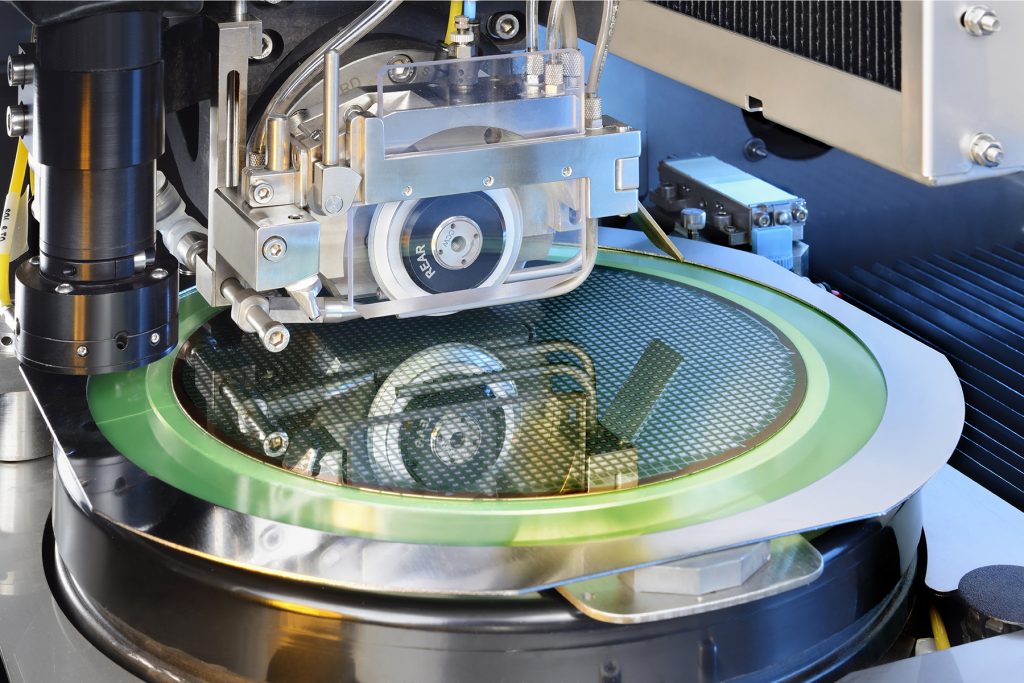

Hubbed dicing blades are essential for cutting semiconductor wafers into individual dies and are available in various grit sizes, diamond concentrations, and binder hardnesses.

“We’re delighted to have been appointed to distribute K&S’s high-quality hubbed dicing blades in Austria, Germany, the Netherlands, and Portugal,” commented Matt Brown, Director of Inseto. “These are countries where our technical specialists are already well known and are supporting customers active in semiconductor manufacturing.”

Inseto has been supplying dicing blades in the UK and Ireland for 16 years and has extensive expertise in all technical aspects of wafer dicing. For instance, silicon, being relatively soft, can typically be cut in a single pass, while compound semiconductors such as silicon carbide and gallium nitride, which are harder and more brittle, often require multiple cuts to minimise the risk of sidewall cracking and chipping.

Brown added: “Cut quality is determined by factors such as the size of the diamonds in the blade, the rate at which the binder material releases them (i.e. blade wear), the RPM at which the blade is spun, and the speed at which it is moved through the wafer. Cooling and the use of surfactants also influence cut quality, so there are many variables to consider. Given the high cost of fabricating wafers, it’s crucial to avoid damaging any dies during the dicing process.”

As a supplier of dicing saws and a range of processing equipment, Inseto can also advise customers early in their projects on issues such as optimum ‘street’ widths between dies. There is naturally a trade-off between maximising the number of dies on a wafer and being able to cut between them without causing damage. Inseto is also a supplier of semiconductor wafers and operates a dedicated online store.

“Our appointment by K&S to distribute hubbed blades in four additional European countries is fantastic news in itself,” concluded Brown. “It also represents broader recognition of Inseto’s in-house expertise in all aspects of semiconductor manufacturing and our ability to help customers achieve excellent economies of scale and return on investment.”

Visit the Inseto (UK) Ltd website for more information on Inseto’s Geographical Remit Extends: Now Supplying Wafer Dicing Blades in Austria, Germany, Ireland, the Netherlands, Portugal and the UK