Oil Tank Floor Corrosion Inspection

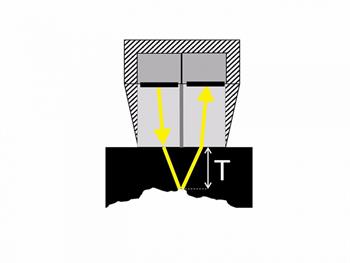

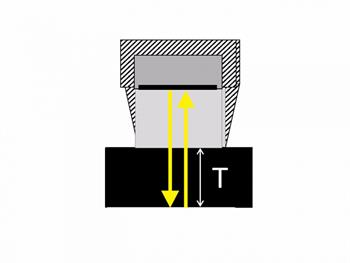

Above ground Oil Storage Tanks usually have a set of NDT inspection requirements must be met, aimed at detecting Corrosion Pitting. This entails a complete bottom scan, including the annular ring area, which is often carried out via the MFL or SLOFEC method. The floating roof will be measured on the top and bottom side, sleeves and welding and the thickness of the tankwall will be measured. Magnetic Flux leakage is a qualitative not quantitative inspection tool but is a reliable detector of corrosion on tank floors. Due to the environmental and physical restrictions encountered during real inspections no reliable quantification of indications is possible. Amplitude alone is an unreliable indication of remaining wall thickness as it is more dependent on actual volume loss. Defects exhibiting various combinations of volume loss and through wall dimension can give the same amplitude signal. Couple to this the continually changing spatial relationship of magnets, sensor and inspection surface, it is absolutely clear that an accurate assessment of remaining wall thickness is virtually impossible. Truly quantitative results can only be obtained using a combination of Ultrasonics and Flux Leakage. The Sonatest Rapidscan 2 linear scanning system with the Corrosion WheelProbe is a major advance on the conventional techniques providing features that help overcome problems and increase the probability of detection and therefore correlation with the MFL inspection. The design of the WheelProbe allows use in the overhead and vertical positions as well as floors, making it ideal for all tank inspection requirements. -Scan mapping in both ToF (Depth) and Amplitude makes detection of small conical pits more reliable, as often the amplitude loss over the cone cannot be detected. Using the corresponding amplitude B-Scan allows differentiation between the top and bottom surface wall loss, whilst helping to differentiate between corrosion defects and, most importantly, plate inclusions that can easily be mistaken when using a single A-scan. The C-Scan allows the minimum thickness to be found over the area scanned, and the resulting pictorial image is much easier to evaluate.Visit the Sonatest Ltd website for more information on Oil Tank Floor Corrosion Inspection