Hydrogen Blistering Inspection using Phased Array

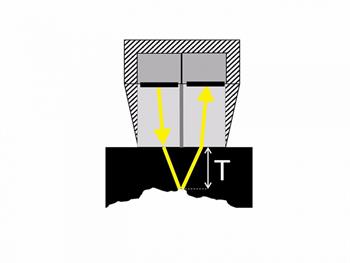

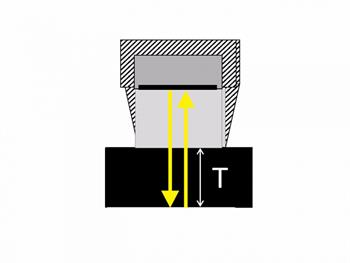

Hydrogen blistering usually occurs in ‘sour’ systems where oil or gas contain large amounts of hydrogen sulfide. At high temperature when hydrogen atoms diffuse into the steel, hydrogen molecules then form an internal defects or inclusions that usually migrate to become a small delamination. Over time, this can form voids or ‘blisters’ which may eventually generate enough pressure to rupture the metal. Inspecting using Phased Array L-Scan gives an unambiguous means of detecting regions of hydrogen blistering. BOX EXTRACTOR, C-SCAN & TOP VIEW functions are powerful tools to detect and give clear indications of the size and shape of the blistered region. The fast PRF and 2D encoding capacity of the VEO enables fast scanning of significant area and packages the resulting data into a comprehensive 2D MERGED view. UTDATA can be analysed and reports generated directly on the instrument, or in the office using the Sonatest PC based software UTSTUDIO. Raw data can also be exported to CSV for customised analysis.Visit the Sonatest Ltd website for more information on Hydrogen Blistering Inspection using Phased Array