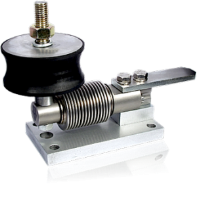

Load Cell Mounting SHKM-355

In some applications, load cells may be subjected to vibration or even shock loads. Also when ever several load cells (Bending and Shear Beam type load cells in particular) are built into a scale or platform, some flexibility must be introduced into the mechanical design to allow for expansion (due to temperature) and the bending and twisting of the frames under load. If not, forces will be created between the individual load cells which could cause significant measurement errors.A simple and cost effect way of eliminating these issues is to use a type of fatigue resistant elastomer bearing. An elastomer bearing typically consists of two metal plates which are held together by layer of vulcanised neoprene rubber.

The SHKM-355 is specifically designed for the load cell model 355 . The thickness and Shore hardness of the neoprene material has been selected for each load cell capacity range, hence the different shapes and sizes.

The main function of the rubber bearing is to prevent side loads and moments being transferred to the load cell thus preventing measurement errors. In addition, the SHKM-355 reduces the amount of vibration that reaches the load cells and protects the it from shocks caused by dynamic loads.

Optional alloy steel base kit (BK-355) available separately.

Visit the Sensor Techniques Limited website for more information on Load Cell Mounting SHKM-355