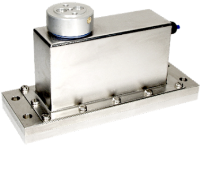

Load Cell 240

All packaged foods must meet the legal weight requirements. This involves ensuring that the net weight of the contents are within set tolerances.The filling and packing of most food products is carried out by automatic packing machines with integrated weighing systems. In some instances the weighing of the product may involve the product falling from a height into the weigh hopper. In cases like this the shock caused by the product falling into the hopper leads to some very high dynamic forces and extremely high numbers of load cycles (ringing).

The oil damped load cell model 240 was developed for this application. The oil damping not only reduces the kinetic energy caused by the impact it also allows the load cell to settle the correct weight value much quicker.

The Model 240 is manufactured using an optimised complex machining process. This ensures that there will be no measurement error when the load is placed off centre, eg in a corner of a platform.

Installation of the model 240 is very easy. The load cell is bolted down to stiff frame or plate using the four holes in its base plate. The platform top is attached to the head of the load cell using the two screws in the load cap. The output of the load cell is then taken to an amplifier, PLC or digital display.

The 240 load cell is fitted with a 6 core shielded cable as standard. Special cables and lengths are available on request.

The Model 240 is manufactured using an optimised complex machining process. This ensures that there will be no measurement error when the load is placed off centre, eg in a corner of a platform.

Installation of the model 240 is very easy. The load cell is bolted down to stiff frame or plate using the four holes in its base plate. The platform top is attached to the head of the load cell using the two screws in the load cap. The output of the load cell is then taken to an amplifier, PLC or digital display.

The 240 load cell is fitted with a 6 core shielded cable as standard. Special cables and lengths are available on request.

Visit the Sensor Techniques Limited website for more information on Load Cell 240