Wire Bond Shear Test: Microelectronic Devices

Wire Bond Shear Test Overview:Shear Testing Fine & Large Wire Diameters Shear Test Ball Bonds according to ASTM F1269Shear Test Wedge BondsManual and automated shear testingTest wire and ribbons

Wire bond shear testing is used as a process control method on semiconductor and related microelectronic devices, to determine the adhesion of ball (typically gold, copper or silver/palladium wires) and wedge bonds (typically large aluminium, fine aluminium/silicon and gold wires). Ideally, wires should form an intermetallic joint with the bond surface and not simply lift-off when sheared.

Wire bond ball shear testing is covered by the external standard to ASTM F1269.

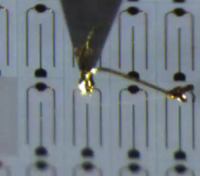

The principle behind bond shear testing is to apply a wedge shaped tool perpendicular to the materials top surface and against the object being tested. The test object is then moved against the shear tool until the bond interface or test object fails (destructive testing).

The shear tool position during testing is critical for accurate and repeatable test results. Nordson DAGE cartridges find the device surface using an sensitive touchdown feature. High precision positioning provides shear height accuracies of +/- 0.25 microns. Touchdown is achieved using a patented load cartridge clamping system which ensures every bond is sheared at the same height relative to the surface that it is bonded on.

Accurate shear testing requires:

Precise multi-axis controlRepeatable shear height and test speedLow landing forces (soft landing)Firm clamping of the toolZero hysteresis

Wire Bond shear testing is performed on:

Fine wire diameters (typically 12.5 to 50 micron) Large wire diameters (typically 100 to 500 micron)Ribbons (typically up to 2000 x 250 microns)

Shear test Cartridges are available that cover a range of forces. An appropriate shear tool should also be used, which should be at least as wide as the object being tested.

Small geometry bump shear testing (Fine Pitch) is also performed on wafer and other bumped applications. Nordson DAGE offers manual and fully automated equipment specifically for this application.

PreviousNext

Further Information

File

Knowledge Base: Understanding Shear Testing

Download

File

Nordson-DAGE Bond Testing Equipment

Download

Visit the Inseto (UK) Ltd website for more information on Wire Bond Shear Test: Microelectronic Devices