Stud Die Pull Test: Microelectronic Devices

Stud Die Pull Test Overview:Stud Die Pull Testing of Bonded DieStud Pull Test Components & Flat SubstratesTest Thin and Fragile Die Under TensionApplies Even Forces During TestingCompliments Die Shear TestDestructive Testing (as studs are glued to the die)

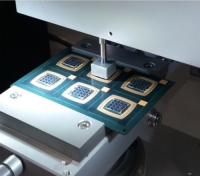

Stud die pull test is used as a process control method to determine the adhesion of die or other flat components and substrates and is ideal for fragile, thin, stacked or large area die, as the forces are applied in pure tension, evenly across the component being tested.

This is achieved by gluing a disposable stud to the top surface of the die and applying perpendicular forces away from the die bond interface. In the case of "Dage Stud Die Pull Accessories", these forces are applied either vertically in the Z axis using a pull test cartridge or horizontally in the Y axis using a die shear cartridge. Typically, a rapid curing cyanoacrylate glue is used to bond the stud to the die; a range of studs are available to suit various die sizes.

Stud die pull test is a complementary technique to the more common die shear test, with both methods being used to get a full understanding of the die-substrate bond strength. As shear testing applies its load against one edge of the test object, this can cause bending of the die or substrate during the test, so the stress state becomes a combination of shear and tension. This bending gets worst as the die area increases relative to the thickness of the die. Stud-pull testing eliminates this issue by distributing the forces more evenly over the top surface

PreviousNext

Further Information

File

Nordson-DAGE Bond Testing Equipment

Download

Visit the Inseto (UK) Ltd website for more information on Stud Die Pull Test: Microelectronic Devices