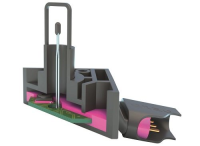

Sensor Encapsulation

Adhesive Key FeaturesHigh-purity adhesives for bare die and component encapsulationLow CTE to prevent warpage and breaking of wirebondsHigh Tg to minimise stresses, both during and after cureExcellent protection against mechanical stress (temperature, vibration, etc.)Very high chemical resistance

Adhesives for IC and sensor encapsulation in the automotive industry must withstand extreme chemical stresses and elevated temperatures from -65°C to +180°C.

When encapsulating bare ICs (a process sometimes known as chip-on-board, or COB), two options are used: A one-stage process called GlobTop for small-area encapsulation, where an adhesive with a tailored viscosity is dispensed onto the surface of the die. The controlled flowing behaviour of the adhesive results in a dome of adhesive that protects the IC and the wire bonds, and the adhesive is then heat-cured to harden the dome. When the encapsulation area is too large to use a GlobTop (because of the dome height), then a wall or Dam is dispensed around the IC using a high viscosity adhesive, and the interior is then Filled with a low viscosity version of the same adhesive. Both adhesives are cured simultaneously.

Two-part versions of the same adhesives are used to encapsulate whole PCB's and the components assembled onto them. These adhesives offer long term protection against chemicals such as diesel, petrol and oils, and also against the temperature extremes seen during shipment and lifetime of the automobiles.

1234PreviousNext

Sensor Encapsulation Adhesives Technical Downloads

File

DELO MONOPOX Selection Chart

Download

File

DELO-DUOPOX Selection Chart

Download

File

DELO Potting Compounds & Encapsulants Brochure

Download

File

DELO Bonding in Electronics Brochure

Download

Visit the Inseto (UK) Ltd website for more information on Sensor Encapsulation