Electric Motor Assembly

Adhesive Key FeaturesReduced production cycle timesImproved rigidity in constructionIncreased impact protectionSound and vibration deadeningReduction in weight

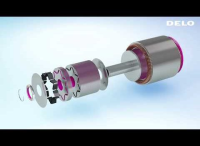

Electric motors are omnipresent in everyday life. Through technological advancements, they have become smaller and more efficient, creating new challenges for joining technology. Bonding provides numerous advantages in terms of production and operation, allowing engineers designing motors to choose from a wide range of adhesives. However, electric motors are not only used for emission-free driving, they are also found in window regulators and seat adjusters. In fact, they can be found everywhere - in electric bikes, in tools, even in our kitchens.

Manufacturers of efficient electric motors rely more and more on rare earth magnets. Since they are prone to corrosion, their surfaces are treated with a coating in the form of passivation, nickel plating, or epoxy resin plating. This coating may be damaged during assembly, openly exposing the magnets to direct environmental influences. Compared to conventional joining methods, bonding offers many advantages. It is a particularly suitable option for three steps in the assembly of electric motors: joining magnets and lamination stacks, joining shaft and rotor, and joining stator and housing. Adhesives not only compensate for higher manufacturing tolerances and prevent fretting corrosion or contact corrosion, but also provide impact resistance, which is essential to withstand the high dynamic forces of electric motors. Their vibration-damping characteristics reduce noise and provide acoustic improvement. Thanks to a homogeneous stress distribution, adhesives are able to compensate for thermal stress that may be generated due to different coefficients of thermal expansion between stator and housing. Their gap-filling properties help prevent slippage and play in the area of the shaft.

12345PreviousNext

Electric Motor Adhesives Technical Downloads

File

DELO MONOPOX Selection Chart

Download

File

DELO-ML Selection Chart

Download

File

DELO Structural Bonding Brochure

Download

Visit the Inseto (UK) Ltd website for more information on Electric Motor Assembly