Bonding of Electric Motors

DELO-ML Key FeaturesOne-part anaerobic-curing adhesivesCure in the presence of metal and the absence of oxygenExcellent thermal & chemical resistanceDual-curing option to "freeze" the visible part of the adhesiveFlexible, impact-resistant and tension-equalising

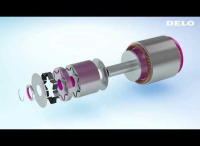

Increasingly, magnets used in electric motors are adhesive-bonded rather than using conventional mechanical joining methods. Using adhesives gives the advantage of evenly distributing stresses (rather than concentrating them on the mechanical joint), reducing vibration noise, increasing corrosion protection, and eliminating of component damage during the joining process.

DELO-ML anaerobic adhesives offer excellent thermal stability up to 220°C, excellent chemical resistance, tension-equalising properties, and an increased gap-filling capability over mechanical joints. Additionally, using a dual-cured anaerobic adhesive offers fast light-fixation on the visible part of the bond.

12345PreviousNext

Magnet Bonding Adhesives Technical Downloads

File

DELO Adhesives for E-Motors Brochure

Download

File

DELO-ML Anaerobic Adhesives Selection Chart

Download

File

DELO Structural Bonding Brochure

Download

Visit the Inseto (UK) Ltd website for more information on Bonding of Electric Motors