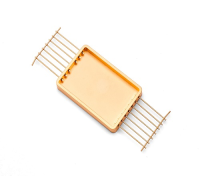

Bathtub Packages and Flatpacks

Bathtub Packages and Flatpacks Key FeaturesCompression sealed and matched sealed optionsComplete in-house plating capabilitiesAll packages manufactured to MIL-STD-883 as minimumFull in-house testing capability to MIL-PRF-38534

Egide offers comprehensive solutions to the more traditional hybrid thick-film technologies. It has been manufacturing glass-to-metal-sealed packages since its inception in 1986, so has a long and extensive history with these types of packages. It has numerous conveyor furnaces for all joining process, from low-temperature soldering to high-temperature brazing.

A wide range of bathtub packages (sometimes called "plug-ins") and flatpacks, usually made from KovarTM, compliments more specialised requirements in the Power & RF markets. Fully automated, computer-controlled electroplating lines ensure that the most critical process in hermetic package manufacturing is under complete control.

Egide offers both compression sealing and matched sealing. In compression-sealed packages, the reliability of the seal is guaranteed by the thermal expansion of glass and metal creating the necessary concentric compressive stress to meet stringent hermeticity requirements. The matched sealing process uses the match of the thermal expansion coefficients of Kovar and glass over a wide temperature range. An oxide layer created between metal and glass provides for the hermeticity and electrical insulation.

12345PreviousNext

Bathtub Packages and Flatpacks Technical Downloads

File

Egide Design Guidelines - General Process Materials

Download

File

Egide Design Guidelines - Standard Routing Design

Download

Visit the Inseto (UK) Ltd website for more information on Bathtub Packages and Flatpacks