The Different Uses Of An Air Compressor

Air compressors power a range of tools and equipment in various fields, from construction and manufacturing to home DIY projects. This article explores the common question, “What is an air compressor used for?” and their benefits in different applications.

Key Takeaways

Air compressors are versatile tools used in various industrial, construction, automotive, and household applications, with types including piston compressors, rotary screw compressors, and oil-free compressors, each designed for specific tasks and benefits.

In industrial settings, air compressors are critical for powering machinery, automating processes, and maintaining high precision and hygiene in manufacturing, food and beverage, and pharmaceuticals.

Choosing the right air compressor involves assessing CFM and PSI requirements based on the tools and tasks, considering the work environment, and evaluating the size and portability needs for efficient and effective use.

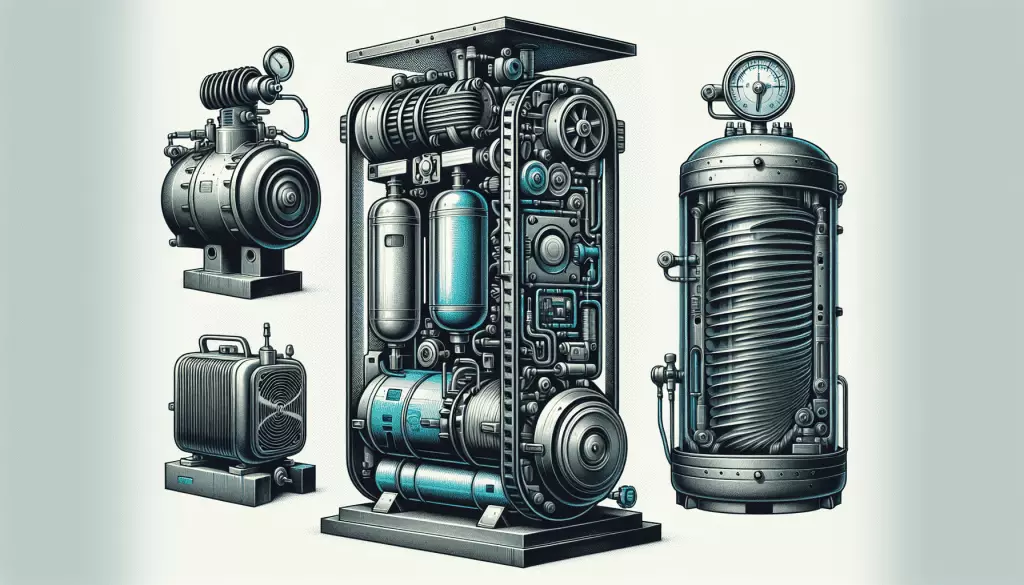

Common Types of Air Compressors

Air compressors come in various types, each designed to cater to specific needs and applications. The primary function of an air compressor is to convert mechanical power into potential energy stored in compressed air. This stored energy can power various tools and equipment, making air compressors invaluable in many settings. The most common types of air compressors include piston compressors, rotary screw compressors, and oil-free compressors, each offering unique benefits and suited to different tasks.

Grasping the distinctions among various air compressors is fundamental in making an appropriate selection for your needs. Whether you require a high-pressure system for industrial use or a portable unit for home projects, knowing how each type works will help you make an informed decision. We will examine the specifics of piston compressors, rotary screw compressors, and oil-free compressors, observing their operation and optimal use cases.

Piston Compressors

Piston compressors, also known as reciprocating compressors, utilize a piston and cylinder system to compress air. The basic working principle involves:

- The piston moves downwards, creating a vacuum that draws air into the cylinder.

- As the piston moves up, it compresses the air to a higher pressure.

- The compressed air is then released into a storage tank.

- This process is continuous, allowing for a steady supply of compressed air.

There are two main types of piston compressors: single-phase and dual-phase. Single-phase compressors compress air in one stage and are suitable for applications requiring moderate pressure. Dual-phase compressors, on the other hand, compress air in two stages, resulting in higher pressure and efficiency. These compressors are ideal for heavy-duty tasks and can power a variety of pneumatic tools, making them a popular choice in both industrial and workshop settings.

Rotary Screw Compressors

Rotary screw compressors are another common type of air compressor known for their efficiency and continuous operation. These compressors use two internal screws rotating in opposite directions to trap and compress air. The design of rotary screw compressors allows for a smooth and consistent flow of compressed air, making them ideal for applications that require continuous use.

One of the key advantages of rotary screw compressors is their ability to maintain high performance over long periods without overheating. They are often used in industrial settings where a constant supply of compressed air is necessary. However, it’s important to consider the specific requirements of your application, as rotary screw compressors can have certain pros and cons depending on the use case.

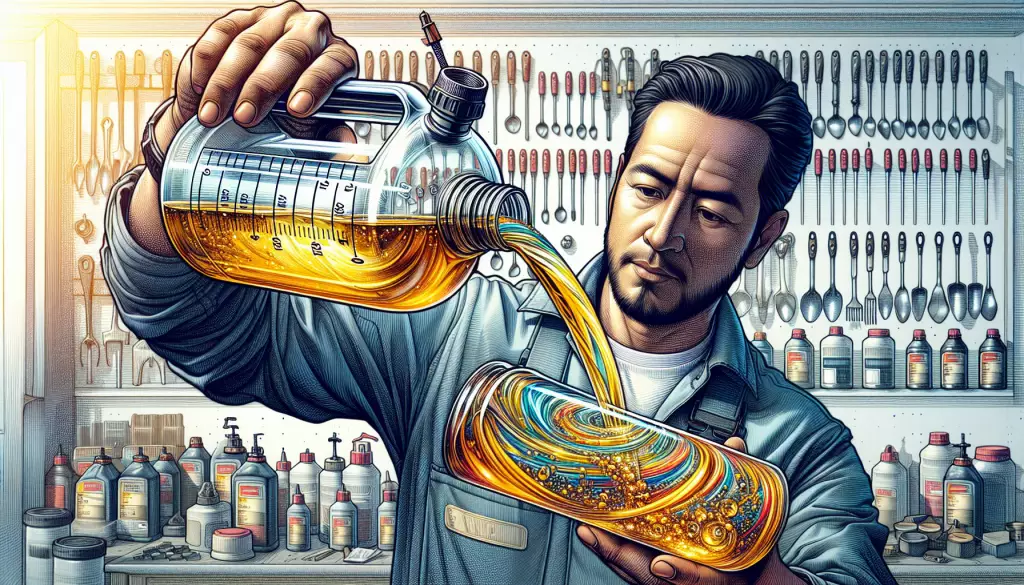

Oil-Free Compressors

Oil-free compressors are designed to be lightweight, compact, and require less maintenance compared to oil-lubricated air compressors. These compressors use special coatings and materials to avoid oil contamination, making them suitable for applications where cleanliness is paramount. They are commonly used in environments such as laboratories, clean rooms, and the food and beverage industry.

The benefits of oil-free compressors include:

- Less complexity and more affordability due to the lack of oil in the compression chamber

- Less upkeep and low maintenance, making them convenient for users

- They are highly portable due to their compact design, which is beneficial for tasks that require mobility.

Industrial Applications of Air Compressors

Air compressors play a vital role in various industries, providing the necessary power and efficiency for a wide range of applications. From manufacturing to pharmaceuticals, their versatility makes them indispensable in many industrial processes. Compressed air systems can be adapted to maintain power even in harsh and dirty environments, further highlighting their robustness.

In industrial settings, air compressors power machinery, automate processes and ensure precise control of production lines. Industries like chemical production, mining, and automotive manufacturing rely heavily on them, which require high air pressure and consistent performance. Subsequent subsections will focus on specific industrial uses, showcasing the role of air compressors in enhancing efficiency and productivity.

Manufacturing and Packaging

In the manufacturing and packaging sectors, air compressors are crucial for:

- Automating machinery

- Monitoring production processes

- Powering positioners, clamps, and stamping machines, ensuring that production lines operate smoothly and efficiently

- Compressed air is also used in the plastic and packaging industry to form and blow mould objects like bottles and containers.

Air compressors enable the use of pneumatic systems to transport raw materials and fill moulds in packaging systems. This not only speeds up the production process but also ensures precision and consistency in the final products. The ability to maintain high air pressure and continuous operation makes air compressors an integral part of manufacturing and packaging operations.

Food and Beverage Industry

The food and beverage industry relies heavily on oil-free compressors for several reasons:

- They maintain high standards of hygiene and prevent contamination.

- They are used in packaging processes to create a vacuum that seals products, ensuring freshness and preventing leakage and contamination.

- They are essential for maintaining product quality and safety.

Compressed air is also utilized in food processing tasks such as peeling vegetables and filling pastries, providing a more efficient and sanitary method of handling food products. Additionally, air compressors play a key role in packing and palletizing products, further streamlining operations within the food and beverage sector.

Pharmaceuticals

In the pharmaceutical industry, maintaining precise pressure control and sterile conditions is critical. Air compressors are used to maintain pressure in mixing and holding tanks, ensuring the accurate handling and processing of ingredients. This consistency is vital for producing high-quality pharmaceutical products.

Furthermore, air compressors provide a reliable power source for various tools and systems in healthcare settings. They are crucial for maintaining sterile environments and ensuring the smooth operation of pharmaceutical production lines. The use of air compressors in pharmaceuticals underscores their importance in industries where precision and cleanliness are paramount.

Construction and Contractor Uses

On construction sites, air compressors are an essential power source for a variety of pneumatic tools. These tools are lighter, safer, and easier to maintain compared to their electric-powered counterparts, making them highly preferred in the construction industry. Compressed air offers a reliable and efficient energy source, capable of powering multiple tools simultaneously and reducing the need for individual power sources. Some common pneumatic tools used on construction sites include:

- Nail guns

- Impact wrenches

- Jackhammers

- Paint sprayers

- Air drills

- Air sanders

Having an air compressor on site allows for increased productivity and versatility in completing construction tasks.

Contractor-grade air compressors are designed to handle the rigorous demands of construction sites. They are robust and capable of powering heavy-duty equipment, making them invaluable for tasks such as drilling, grinding, and nailing. Additionally, air compressors are used for roadside repairs, ensuring that construction projects can proceed smoothly without significant interruptions.

In the sections below, we will delve deeper into these applications.

Powering Pneumatic Tools

Pneumatic tools, such as jackhammers and drills, are commonly powered by air compressors on construction sites. These tools rely on compressed air for countersinking, reaming, and tapping holes, making them essential for various construction tasks. Sanders powered by air compressors are also used to smooth surfaces, ensuring high-quality finishes in construction projects.

Air compressors, with their versatility, can power an array of air-powered tools, including power pneumatic tools such as:

- Nail guns

- Paint sprayers

- Air drills

- Impact wrenches

- Air hammers

- Air sanders

This flexibility makes them invaluable on construction sites, where different tools may be required for various tasks. The ability to power multiple tools with a single air compressor enhances efficiency and productivity, making construction projects more manageable and cost-effective.

Roadside Repairs and Maintenance

Air compressors are indispensable for roadside repairs and maintenance, providing a quick and efficient solution for various tasks. They can power impact wrenches, which are essential for automotive repairs, such as loosening and tightening nuts and bolts. This capability is particularly useful for tyre maintenance on the road, ensuring that vehicles are in optimal condition.

Air compressors’ versatility makes them valuable tools for roadside repairs. They enhance the speed and efficiency of maintenance tasks, from inflating tyres to operating impact wrenches. Air compressors ensure that roadside repairs can be performed quickly and effectively, minimizing downtime and keeping vehicles on the move.

Automotive and Home Workshop Uses

In automotive repair shops and home workshops, air compressors are invaluable for various tasks. They are extensively used for:

- Inflating vehicle tyres

- Powering paint sprayers

- Operating a range of equipment

- Facilitating high-pressure washing and cleaning, especially for hard-to-reach parts like the engine block.

Pneumatic tools powered by air compressors are favoured over electrical tools in car repair workshops due to their ease of operation and lightweight nature. They are also used for blowing out dust and dirt from vehicle interiors and engine bays during automotive detailing. Subsequent sections will discuss specific applications like inflating tyres and spray painting, demonstrating the practicality and efficiency of air compressors in automotive and home workshops.

Inflating Tires and Other Inflatables

Air compressors make inflating tyres and other inflatables easy. In car repair workshops, they maintain proper tyre pressure, preventing wear and tear and ensuring optimal vehicle performance. For home users, an air compressor allows for quick and easy tyre inflation, making it convenient to check and adjust tyre pressure regularly.

Air compressors are also useful for inflating pool toys, rafts, and other recreational inflatables. This versatility extends their utility beyond automotive applications, making them a valuable tool for various household and recreational tasks. The ability to quickly inflate a wide range of items highlights the convenience and practicality of air compressors.

Spray Painting and Staining

Spray painting and staining tasks are simplified and efficient with air compressors. Using paint sprayers with air compressors offers several benefits:

- Ensures a smooth, even finish on surfaces

- Saves time and effort compared to traditional methods

- Particularly useful for tasks such as spray painting walls, fences, and automotive bodies, where a high-quality finish is desired.

Air compressors are also useful for:

- Airbrushing detailed designs on various surfaces, including models and cakes

- Providing precision and control for intricate and detailed work, ensuring professional results

- Large-scale painting projects

- Detailed airbrushing

Air compressors, including small air compressors, fixed-speed air compressors, and positive displacement compressors, often equipped with an air tank, provide the necessary power and efficiency for these tasks.

Household and DIY Projects

Air compressors are not just for industrial and automotive applications; they also shine in household and DIY projects. The versatility of air compressors makes them ideal for a wide range of home improvement tasks, including:

- Cleaning hard-to-reach areas

- Powering small air tools

- Inflating tyres and sports equipment

- Painting and staining

- Sanding and grinding

- Nailing and stapling

Single-phase compressors, including fixed-speed and variable-speed compressors, are particularly useful in domestic settings and smaller workshops. They are perfect for general DIY tasks like woodwork and metalwork.

Consumer-grade air compressors can also be used for sandblasting, efficiently removing rust or old paint from various surfaces. Additionally, they are practical for inflating bicycle tyres, sports equipment, and other inflatables, bringing convenience to everyday household activities. The sections below will examine these applications more closely, demonstrating how air compressors can streamline and improve DIY projects.

Cleaning Hard-to-Reach Areas

Air compressors make cleaning hard-to-reach areas a breeze. They are commonly used for cleaning and dusting, quickly and efficiently clearing sawdust, wood shavings, and other debris from workspaces. This makes them invaluable in workshops, where keeping the workspace clean is crucial for safety and efficiency.

Compressed air is also highly effective for cleaning electronic components and keyboards without causing damage. Using a narrow nozzle attachment, air compressors can clean window tracks and other tight crevices around the home, ensuring thorough and efficient cleaning. This versatility makes air compressors an essential tool for maintaining cleanliness in hard-to-reach areas.

Powering Small Air Tools

Air compressors power small air tools, such as pneumatic nail guns, staplers, and ratchets, in DIY projects. Homeowners can use air compressors to install hardwood flooring by powering pneumatic nail guns, ensuring precise and efficient installation. Portable air compressors are also commonly used to power brad nailers for small carpentry projects, making them versatile and convenient for various tasks.

Air compressors can power air ratchets, which are ideal for tightening and loosening nuts and bolts in tight spaces. They are also perfect for operating pneumatic staple guns, which can be used for upholstery projects and carpet installation. The ability to power a range of small air tools highlights the practicality and versatility of air compressors in DIY projects.

Choosing the Right Air Compressor

Choosing the right air compressor involves understanding your specific needs and matching them with the appropriate compressor features. To determine the correct air compressor, consider the CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) requirements of the tools you plan to use. Higher CFM and PSI capacities than the tools being powered are generally recommended to ensure efficient operation.

Additionally, when choosing a compressor, it’s important to consider:

- The work environment

- The frequency and duration of use

- For heavy-duty, continuous tasks, stationary compressors with larger tanks are better suited as they provide greater air reserves.

- The size and portability of the compressor, especially if it needs to be moved frequently between job sites.

Determining CFM and PSI Requirements

Calculating the required CFM and PSI based on the specifications of your air tools is critical for choosing the right air compressor. CFM measures the flow rate of air, while PSI measures the pressure; both are essential for determining an air compressor’s capability. To calculate the required CFM, list out all the air tools intended to be used and add up their total requirements based on their specifications.

Consider both the peak and continuous usage of air tools to ensure the compressor can meet demands without frequent breaks. Using a flow meter can provide an accurate reading of the actual airflow and pressure coming from the compressor, helping you make an informed decision. This ensures that the air compressor you choose can handle the demands of your tools and tasks.

Considering Size and Portability

When selecting an air compressor, size and portability are important factors to consider, especially for those who need to transport the compressor between different job sites. Smaller and lightweight compressors are preferred for portability, making them easier to move and handle. Some compressors feature removable petrol storage tanks, further reducing their weight and enhancing portability.

Ensure the compressor is compact enough to fit the available space in your work area, including adequate ventilation and access for maintenance. The right size and portability features will depend on your specific needs and the nature of your tasks. Balancing power and portability ensures that you have a compressor that meets your requirements without being cumbersome.

Summary

Air compressors are versatile tools that play a crucial role in various industries and household tasks. Understanding the different types of air compressors and their specific applications helps in making informed decisions about which compressor best suits your needs. From powering pneumatic tools on construction sites to inflating tyres and cleaning hard-to-reach areas, the uses of air compressors are extensive and invaluable.

Choosing the right air compressor involves considering factors such as CFM and PSI requirements, size, and portability. By understanding these aspects, you can select a compressor that meets your specific needs and enhances your efficiency and productivity. Embrace the power and versatility of air compressors to simplify and improve your tasks, whether in an industrial setting or at home.

Visit the Generator-Pro website for more information on The Different Uses Of An Air Compressor