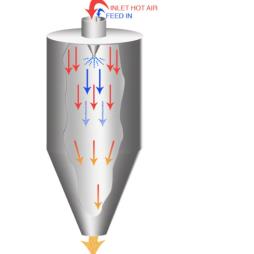

Co-Current Flow Chamber

The Co-Current Flow Chamber design is dictated by the type of atomisation, a disc requires a wider diameter of chamber to allow material to shear from the disc horizontally while the Tall Form chamber is narrower and long, both systems have the same volume of chamber for a given throughput. The shape of the chamber can have a big impact on strength, wider body chambers are in general substantially weaker than Tall Form Chambers for a given volume, a mild steel frame is often used on disc dryers to increase chamber strength. The mild steel frame employed on wide body chambers is covered with cladding. Long term the use of differential metals is a factor in chamber cracking. At European SprayDry chamber design is the heart of the drying system, chambers are manufactured from thick gauge materials giving a greater explosion retention capacity and longer life. For full details please visit our website.Visit the European SprayDry Technologies website for more information on Co-Current Flow Chamber