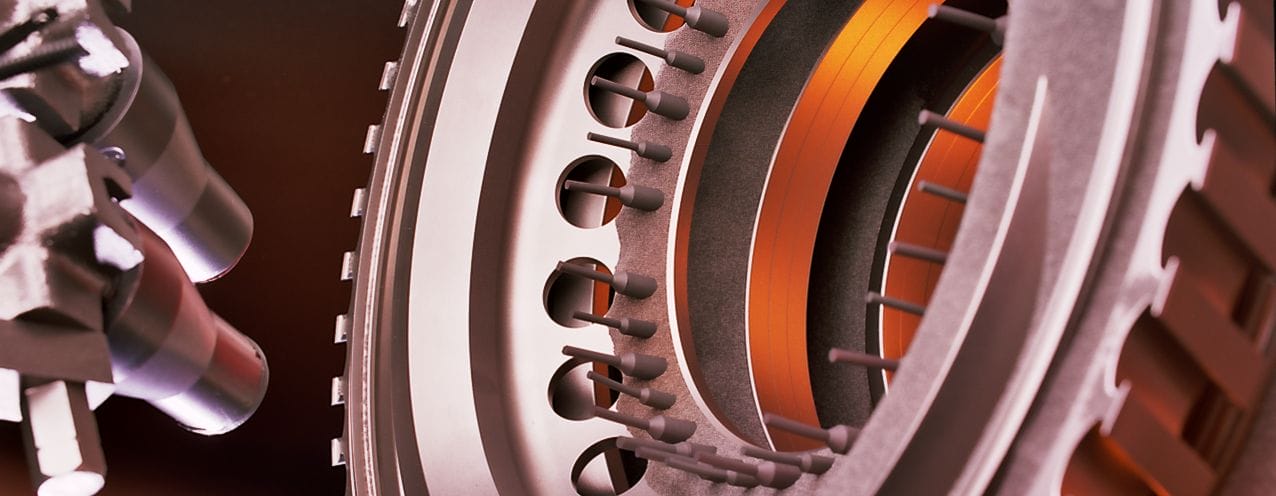

High Velocity Oxy-Fuel Coatings

High Velocity Oxy-Fuel Coatings and Plasma Coatings are applied at our purpose built Derby facility using either a high velocity oxy-fuel (HVOF) or plasma spraying technique.The chosen coating feedstock material, consisting of powder particles (typically 1 to 50 microns); is heated and becomes molten or semi-molten which is then propelled at high velocity onto the surface of the component, as the coating cools it adheres to the surface and forms a bond.

Visit the Curtiss Wright Surface Technologies website for more information on High Velocity Oxy-Fuel Coatings