Understanding Vibration Test Terminology. A Technical Guide

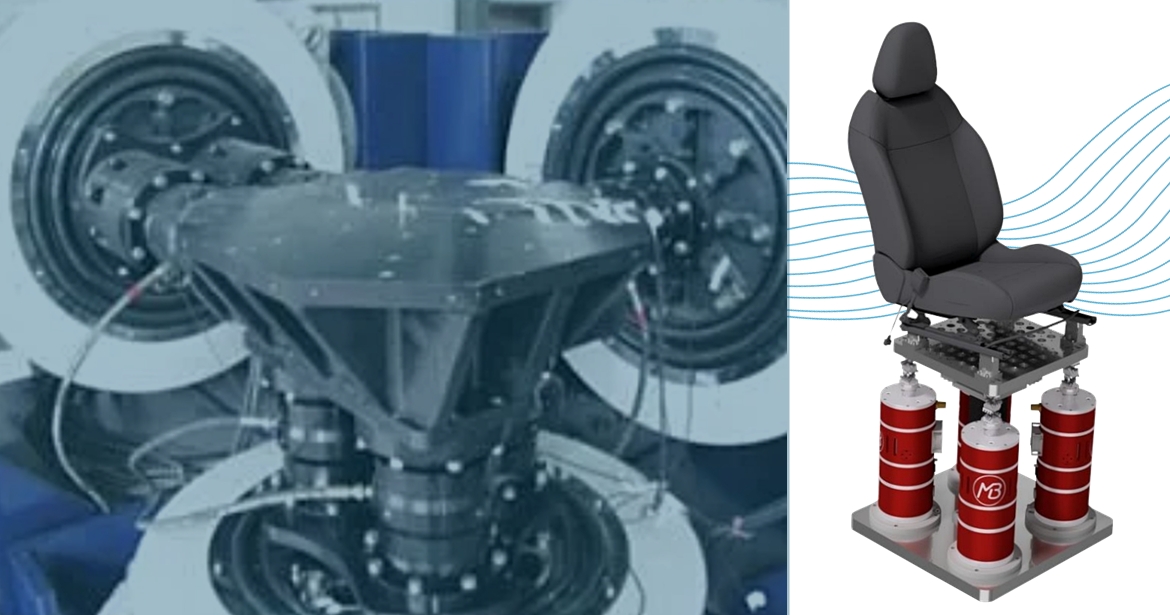

Vibration testing is a vital part of product development and quality assurance across various sectors, including aerospace, automotive, electronics, and more. To navigate vibration testing effectively, it's essential to understand the fundamental terminology associated with it. In this blog, we will explore key terms and concepts related to vibration intensity, including vibration frequency, displacement, velocity, and acceleration.

Vibration Frequency (f)

Vibration frequency, denoted as "f" and measured in Hertz (Hz), is a fundamental parameter in vibration testing. It represents the number of cycles a vibrating object completes per second. The time for a single cycle is known as the "period" (T), and frequency is calculated using the formula:

Vibration Frequency (f) = 1/T

In practical terms, frequency of vibration is akin to the pitch of a sound – higher frequencies correspond to faster oscillations, while lower frequencies indicate slower movements. For instance, a vibration frequency of 100 Hz means the object oscillates 100 times per second.

Displacement (Amplitude) (D)

Displacement, often referred to as "amplitude," measures the distance a vibrating object moves during one cycle. It is typically expressed in metres (m) but can also be given in microns (µm) or millimetres (mm). Displacement can be defined in two ways:

-

Total Amplitude (Double Amplitude): The complete back-and-forth distance the object travels during one cycle.

-

Half Amplitude: The distance travelled in one direction only (e.g., from the rest position to the peak).

Understanding these definitions is crucial as they have different implications for vibration testing and analysis.

Acceleration (A)

Acceleration, denoted as "A," is another critical parameter in vibration testing. It measures how much the velocity (V) of an object changes per unit time. The standard unit of measurement for acceleration in the International System of Units (SI) is metres per second squared (m/s²). However, acceleration is often expressed in the non-SI unit "G," which represents the acceleration due to gravity (approximately 9.81 m/s²).

The relationship between frequency (f), displacement (D), and acceleration (A) in vibration testing is defined by the formula:

A = (2πf)² × D (D: half amplitude)

This formula highlights the interplay between these parameters, showing that changes in frequency or displacement will directly affect acceleration. Therefore, maintaining one parameter constant while altering the others can lead to different vibration conditions.

Velocity (V)

Velocity, denoted as "V," measures the rate of change of displacement over time. It indicates how fast the vibrating object is moving at any given moment during the vibration cycle. Velocity is usually expressed in metres per second (m/s) or millimetres per second (mm/s).

Velocity provides crucial insights into the dynamic behaviour of the test specimen. It complements other parameters such as frequency, displacement, and acceleration by offering additional information about the movement of the vibrating object and its response to external forces. Understanding velocity is essential for evaluating a product’s performance and structural integrity.

Implications of Frequency and Amplitude Changes

Understanding the interaction between frequency and amplitude is vital when planning vibration tests. Two key observations are:

-

Sweep Vibration Testing: When acceleration is constant and frequency is gradually increased, the amplitude decreases as frequency rises. This method is useful for exposing a product to a range of frequencies to identify resonant frequencies and weaknesses.

-

Constant Amplitude Testing: Conversely, when amplitude is kept constant and frequency is increased, acceleration rises with frequency. This is employed when focusing on a specific frequency range.

Neglecting these relationships can lead to transient vibrations affecting the test sample or excessively minimal vibrations, potentially compromising the validity of the results.

In practice, vibration conditions are often defined by maintaining constant amplitude at low frequencies and then keeping acceleration constant once a specific frequency threshold is reached. This approach ensures that the test accurately replicates the environmental conditions or stress factors the product will encounter during its lifecycle.

In conclusion, understanding vibration testing terminology is crucial for conducting effective tests on products and components. By grasping the concepts of vibration frequency, displacement, velocity, and acceleration, along with their interdependencies, engineers and quality control professionals can ensure their testing procedures provide valuable insights into product performance, reliability, and durability.

Visit the CentraTEQ Ltd website for more information on Understanding Vibration Test Terminology. A Technical Guide