Chocolate Drop Line

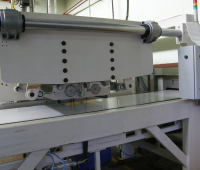

Chocolate drop line depositor designed to make chips of 0.05g to 0.2g @ 20 strokes/minute.The body of the depositor has twin jacketed hoppers manufactured entirely in stainless steel. The depositor is a twin rotary valve with horizontal piston design. Each Chocolate piston drive bar assembly is connected via two links to the main shaft and lever. The shaft is driven by positively and directly by an inline planetary gearbox and servo motor. The maximum stroke of the piston drive bar is 70mm; the radius of the lever is 234mm which gives a total turning angle of the shaft of 17 degrees.

Chocolate piston deposit and suction strokes and speeds are adjusted directly from an Allen-Bradley Panel View 600 unit. Piston suck back can be adjusted for speed and stroke or can be eliminated altogether. 96 pistons are mounted on two drive bars (48 on each) and retained by two keep plates. Pistons can be disconnected and removed for cleaning by lifting the keep plates and extracting them through the drive bar. Each drive bar is supported on bearings by two shafts to ensure a horizontal movement throughout the piston stroke.

The depositor head will oscillate from left to right during the Chocolate deposit stroke and then return to its park position. The head is mounted on linear bearings and driven in line by an Allen-Bradley servo motor and planetary gearbox.

Transfer plates are held in place by two bars and secured with cap head screws which allows for quick exchange of plates but ensures complete clamping. Changing from one nozzle layout to another requires a change of transfer plates and selecting a new programme in the Allen-Bradley PanelView 600 unit.

The chocolate chip line depositor main frame is manufactured in mild steel with a food quality powder coat paint finish in white. The drive cover and door are in stainless steel with a satin finish.

The main drive cover is fully interlocked. The rotary valve and paddle in each hopper are protected from the operator by a guard arrangement.

The depositor head will oscillate from left to right during the Chocolate deposit stroke and then return to its park position. The head is mounted on linear bearings and driven in line by an Allen-Bradley servo motor and planetary gearbox.

Transfer plates are held in place by two bars and secured with cap head screws which allows for quick exchange of plates but ensures complete clamping. Changing from one nozzle layout to another requires a change of transfer plates and selecting a new programme in the Allen-Bradley PanelView 600 unit.

The chocolate chip line depositor main frame is manufactured in mild steel with a food quality powder coat paint finish in white. The drive cover and door are in stainless steel with a satin finish.

The main drive cover is fully interlocked. The rotary valve and paddle in each hopper are protected from the operator by a guard arrangement.

Visit the A.M.P Rose website for more information on Chocolate Drop Line